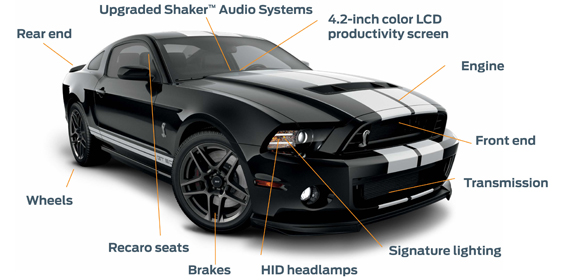

Ford Shelby GT500 Debuts as Fastest, Most Powerful Mustang Ever with 662 Horsepower ,5.8 Litres and V8 engine. It may become one of the greatest mustang of the decade and has been branded as most powerful engine in North America by Ford.

3,852-pound vehicle to a top track speed of more than 200 mph, yet is exempt from gas-guzzler tax at a projected 15 mpg city, 24 mpg highway in North America. The muscle sets a performance-driven design standard with new downforce-generating front grilles, an aggressive splitter, a new quad exhaust system and two new forged-aluminum wheel choices.

The entire cooling system has been significantly updated on the new 5.8-liter engine. It now includes a high-capacity cooling fan, fan shroud with high-speed pressure-relief doors, a more efficient charge air cooler, a higher-flow intercooler pump and an intercooler heat exchanger whose volume is increased 36 percent. These components harmonize to consistently dissipate heat under extreme-use conditions.

“Every change we made is an improvement in horsepower and in airflow,” said Jeff Albers, SVT Powertrain team leader. “The other changes are about making sure the parts can withstand the pressures when the engine is making that power.” – Mich Dearborn

The supercharger design includes four lobes with a 160-degree twist and has a drive ratio that spins 2.64 times faster than the previous model. The inlet air volume also has been increased 33 percent. Boost has been increased from 9 to 14 psi.

Other modifications for improved power include an upgraded camshaft profile, similar to the Ford GT. The cam lift for the intake and exhaust has been increased for improved airflow. Additionally, the redline is held at 6,250 rpm continuously, but allows for an over-rev to 7,000 rpm for eight seconds to extend the time to shift so that acceleration is higher and 0-60 mph and quarter-mile times can be faster.

The diameter of the bore has been upped from 90.5 to 93.5 millimeters to increase displacement and the fuel injector flow has been increased nearly 10 percent to get an equivalent amount of fuel to accompany the extra air.

Once the engine was able to make the power and pressures were increased, SVT made changes to ensure the engine was durable under those conditions. The connecting rods have been redesigned with a tapered, small end where they attach to the pistons. This improved design supports the load on the dome of the piston more efficiently.

Cooling fan capacity has been increased and a higher-efficiency intercooler added to keep the air entering the engine as cool as possible. An efficient, high-capacity flow pump has been added. These measures manage temperatures under extreme conditions.

To ensure the coolant flow is well balanced cylinder to cylinder, the block and heads have been cross-drilled for water to flow through.

A single-piece carbon fiber driveshaft has been upgraded from the current two-piece steel design, which is lighter and stiffer and offers a higher torque capacity and improved NVH (noise, vibration and harshness) qualities.

“With the driveshaft we were able to eliminate a joint and add enough stiffness and drive capacity to get us to our top speed and handle the torque,” said Jamal Hameedi, SVT chief engineer. “The car makes so much power and torque that we needed to go through the entire driveline system to ensure it moves to the wheels in a manageable way.”

The clutch has increased torque and rpm capacity and uses a dual-disc design. The diameter and clamp load have been increased and the clutch-facing material has been revised for additional resistance to burst and improved transfer of power.

Another key piece of the driveline, the transmission, offers upgraded gears, bearings and housing so it can properly manage the torque. The final drive ratio has been changed to 3.31:1 for optimized overall vehicle gearing to complement the high-powered torque produced. Every gear besides fourth has been optimized for competing performance metrics.

The engine also carries over the use of the state-of-the-art Plasma Transferred Wire Arc liner coating, a process that applies a 150-micron composite coating that contains nanoparticles on the internal surfaces of engine cylinder bores, replacing cast-iron liners typically used in aluminum engine blocks.

The new engine also continues to be exempt from the gas-guzzler tax, delivering a projected 15 mpg city, 24 mpg highway. That is 5 mpg better than the 2012 Chevrolet Camaro ZL1. (With Inputs from Mich Dearborn)